Reverse Engineering Technology & Services in Houston, TX

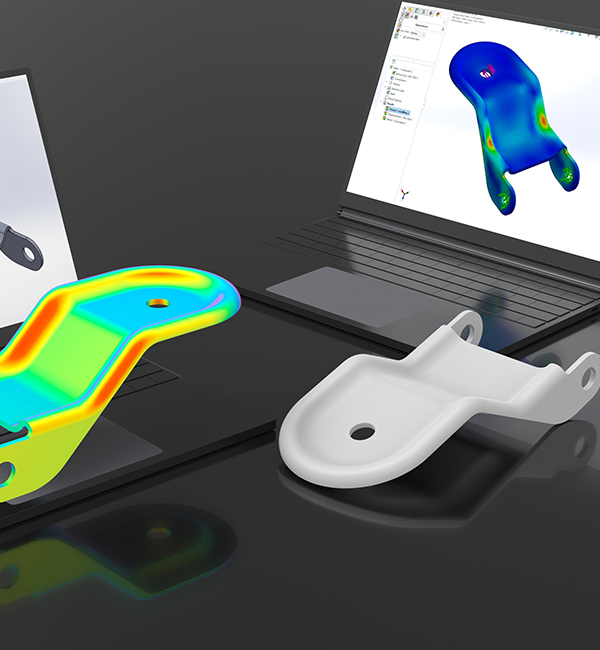

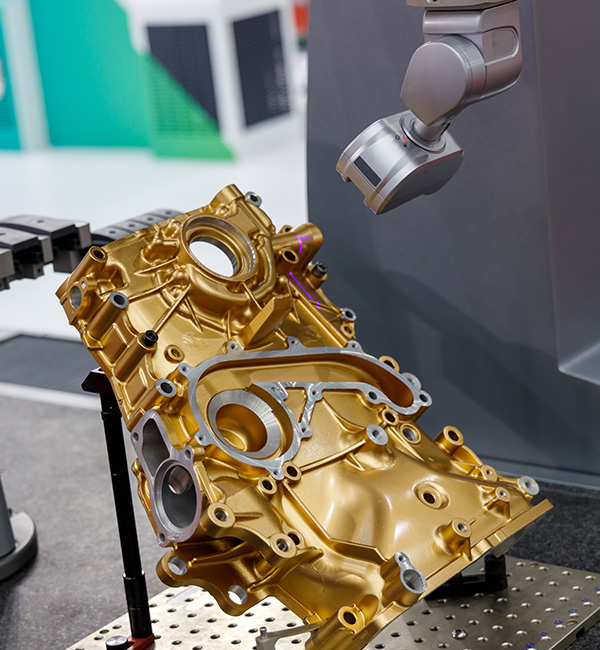

When you have old parts with only 2D data or no drawings at all, HAK Metrology has the tools to provide you with the details you need. We use multiple cutting-edge technologies to generate solid CAD models and drawings, offering full-scope analysis and tolerancing.

Our team captures highly accurate 3D data to build digital replicas, parametric models, or mesh files tailored to your specifications—whether for part replacement, product improvement, or failure analysis.