NimbleTrack-CR Wireless Optical 3D Scanning System for Industrial Metrology

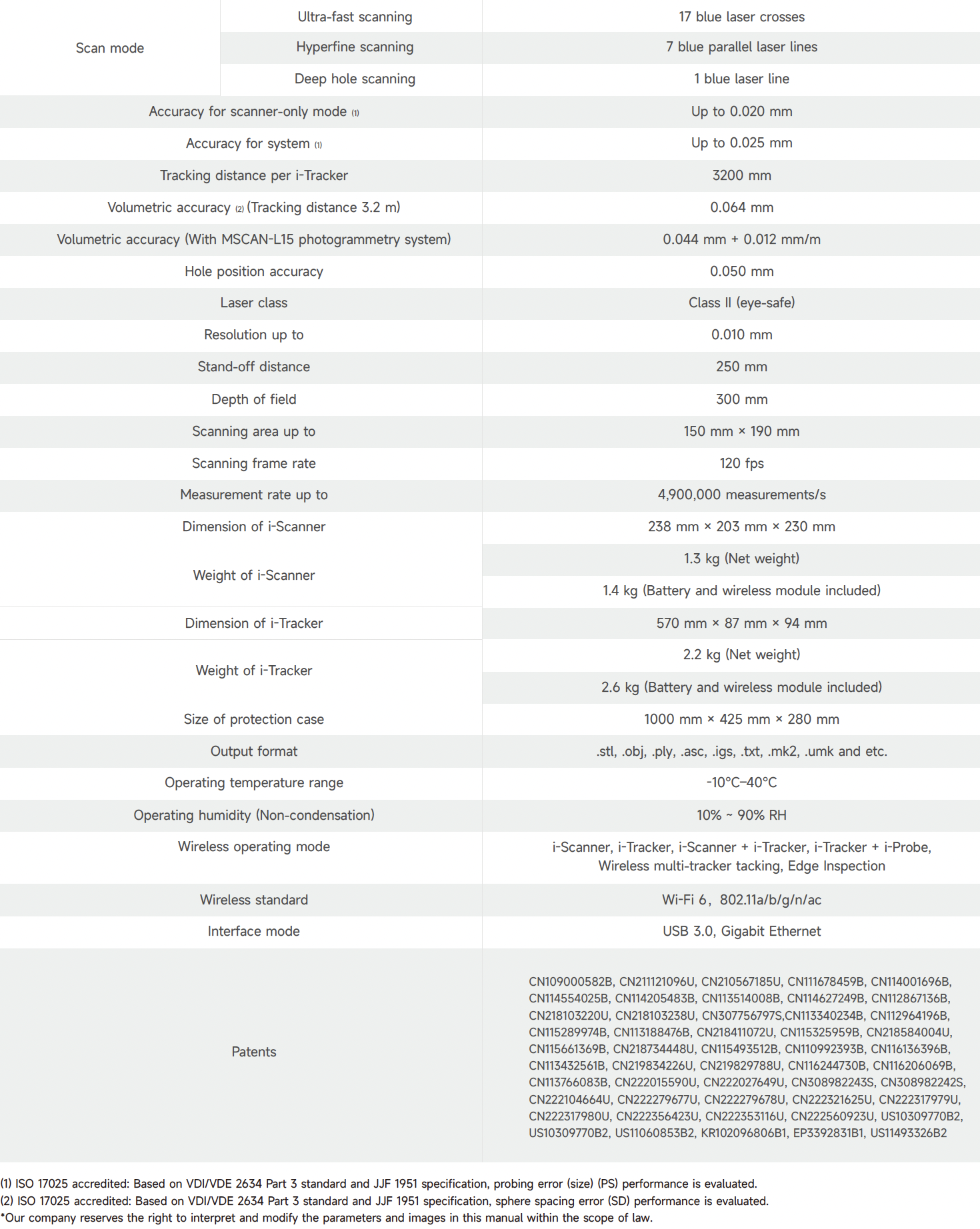

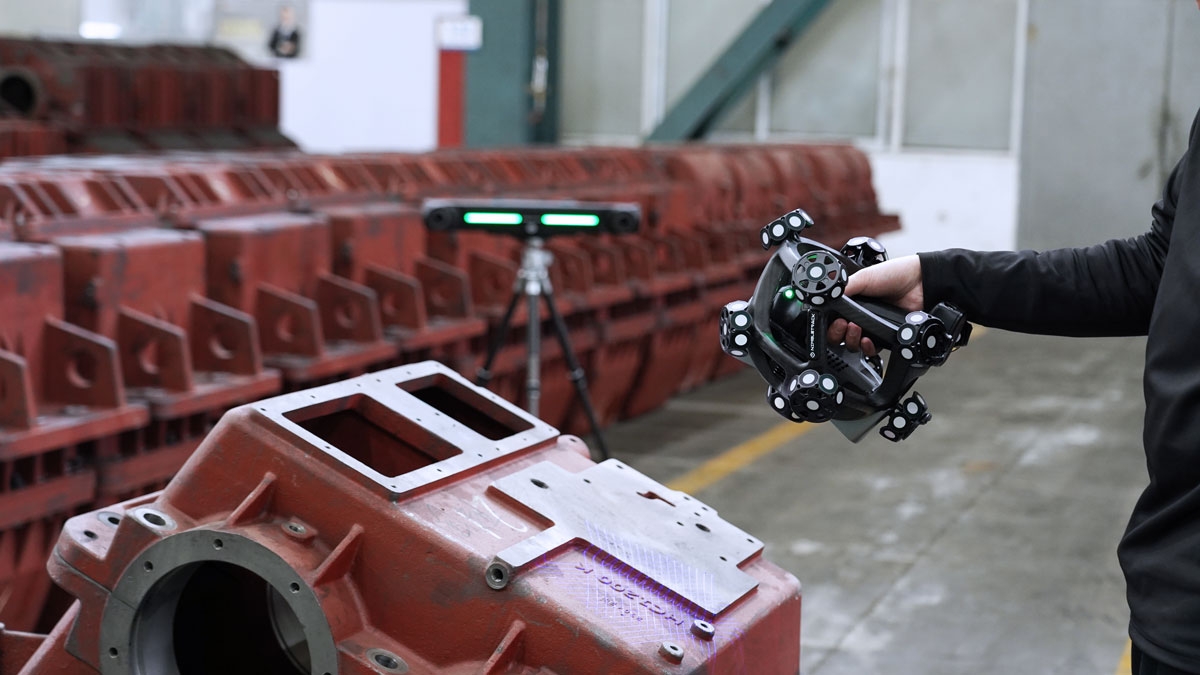

NimbleTrack is a next-generation wireless 3D scanning system that pioneers a truly cable-free industrial workflow. As the industry's first fully wireless, optical metrology-grade scanning solution, it eliminates the limitations and safety hazards associated with tethered equipment. Equipped with a dual-battery cycling system, NimbleTrack ensures uninterrupted operation even during long and complex scanning sessions, allowing users to work freely without worrying about power or cable restrictions.

Building on this advanced wireless architecture, NimbleTrack-CR is engineered for high-precision measurement and exceptional detail capture, making it ideal for both industrial metrology and cultural heritage preservation. Its lightweight, portable design enhances mobility in workshops, laboratories, or field environments, while also making the system easy to transport and store. Powered by high-performance industrial cameras, intelligent algorithms, and edge-computing technology, NimbleTrack-CR delivers smooth, efficient, and highly accurate scanning across a variety of applications.

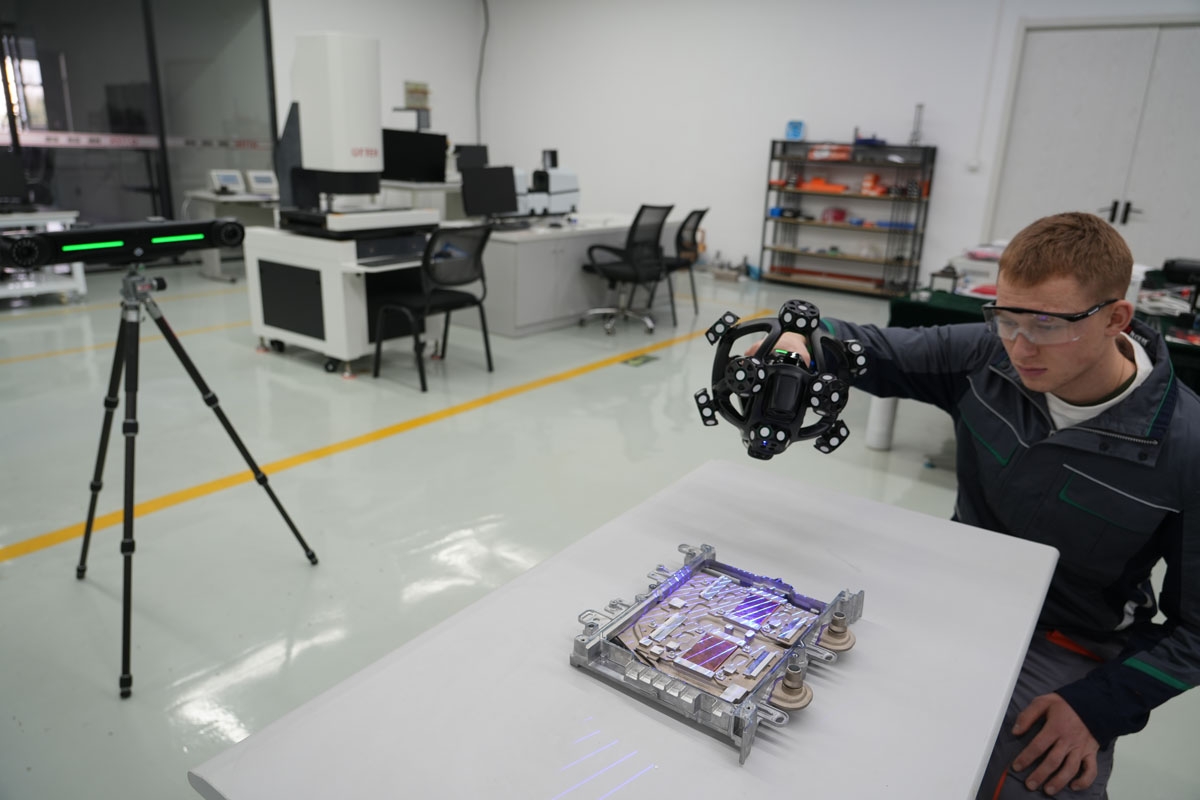

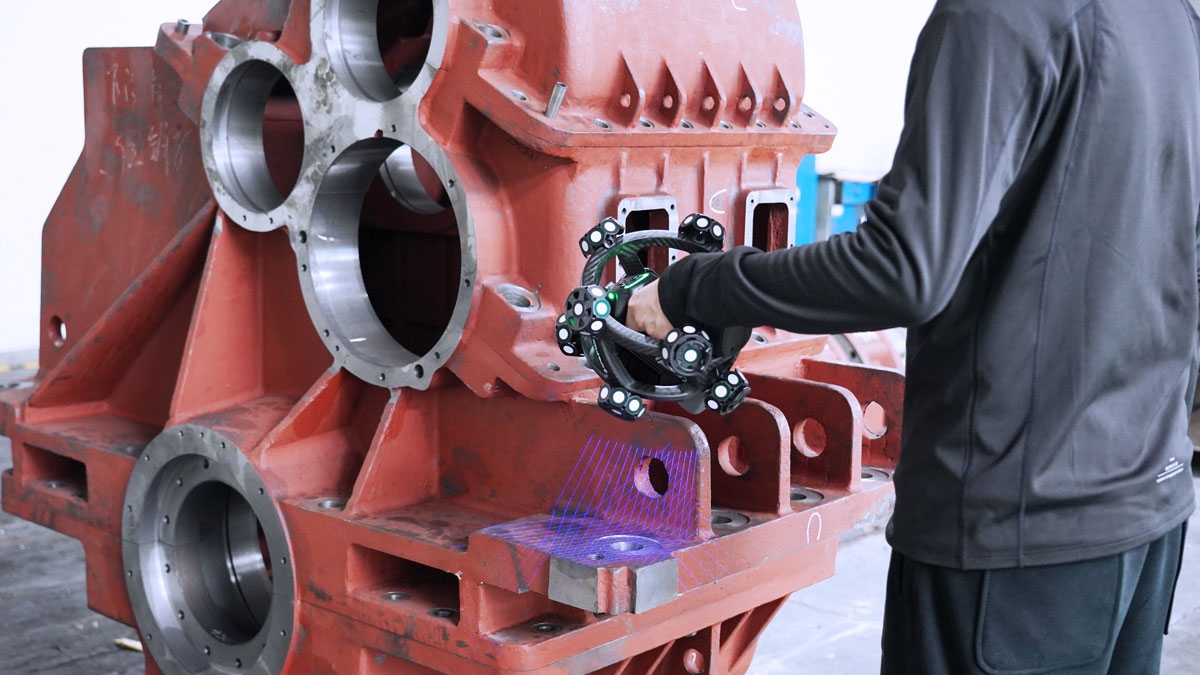

The system supports multiple scanning modes—including ultra-fast, hyper-fine, and deep-hole scanning—ensuring precise measurement of small details, complex geometries, and hard-to-reach cavities without compromising accuracy or workflow efficiency. Together, these capabilities make NimbleTrack-CR a powerful and versatile solution for teams who need reliable, high-performance 3D data capture anywhere.

Advanced Features of NimbleTrack CR

- High accuracy up to 0.025 mm and maximum volumetric accuracy of 0.064 mm across the range.

- Wireless freedom and flexibility, allowing for hassle-free scanning in any environment.

- Advanced cross technology and dual edge computing modules for fast and efficient operations.

- Multiple scanning modes, including ultra-fast, hyper-fine, and deep hole scanning, for diverse applications.

- Enables precise edge detection and extends measurement range for large-scale objects.

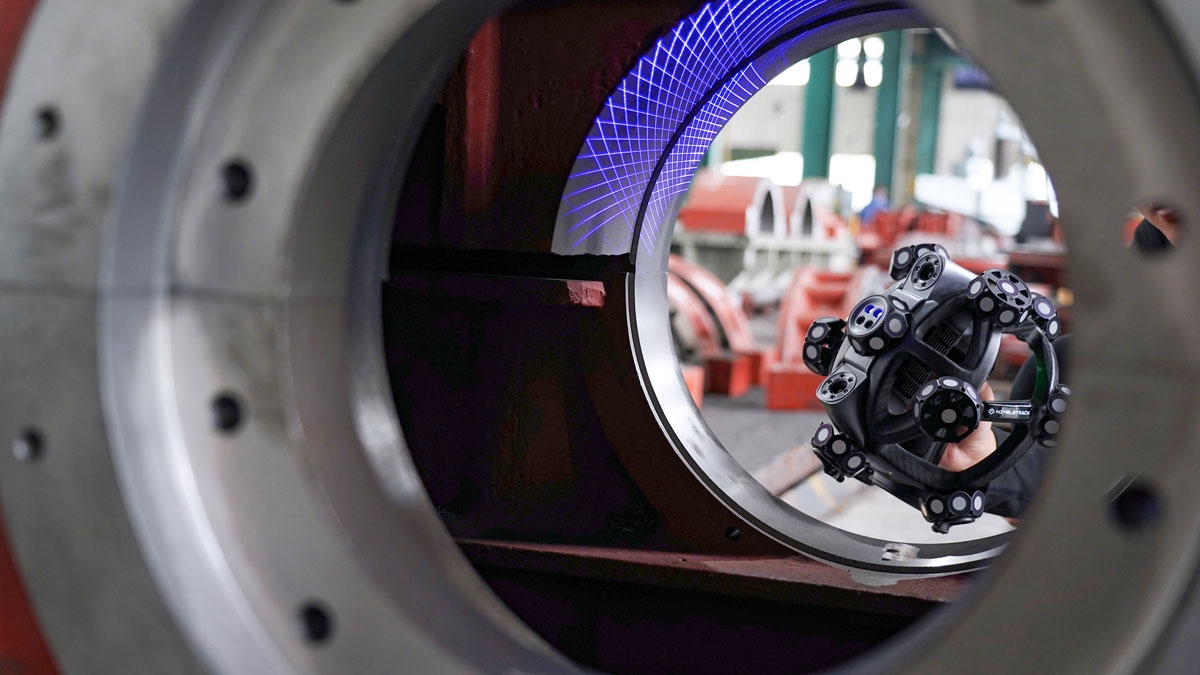

Technical Specifications

- System accuracy of 0.025 mm and scanner-only mode accuracy of 0.020 mm.

- High frame rate of 120 FPS for fast data acquisition without losing detail.

- Temperature range and wireless module for stable data processing and continuous scanning.

- Dual power cycle and compact design for easy transport and storage

- Supports rh wireless operating mode for enhanced precision and flexibility.

Benefits of NimbleTrack Wireless 3D Scanning

The NimbleTrack wireless 3D scanning system delivers high-precision measurement without compromise, offering exceptional accuracy across a wide range of industrial and heritage applications. Its cable-free design provides true freedom and flexibility, allowing users to scan efficiently in workshops, field environments, and confined spaces without setup limitations. With multiple scanning modes and precise edge-detection capabilities, it adapts easily to diverse tasks—from detailed component inspection to deep-hole measurement.

Backed by stable data processing, continuous operation, and seamless wireless performance, NimbleTrack is a dependable solution for quality control, reverse engineering, and cultural heritage preservation.

FAQs About the NimbleTrack-CR 3D Scanning System