KScan-X Wireless Large-Area 3D Scanner for Industrial Precision

Powered by SCANTECH's advanced wireless technology and adaptive photogrammetry, the KSCAN-X is an intelligent, wireless large-area 3D scanner that sets a new standard for large-scale 3D measurements.

Featuring wireless operation, ultra-wide scanning area, extended depth of field, and fast scanning, the KSCAN-X offers smooth and high-precision 3D measurements for ultra-large and large to medium-sized parts across industries such as aerospace, heavy industry, and rail transportation. Designed to boost efficiency and deliver accurate quality control, the KSCAN-X is the ultimate solution for advanced manufacturing.

Advanced Features of the KSCAN-X

Extensive Scanning Area for Ultra-Large Components

Adaptive Photogrammetry for Stable Volumetric Accuracy

Multiple Scanning Modes for Different Applications

Quad Cross Blue Laser Technology

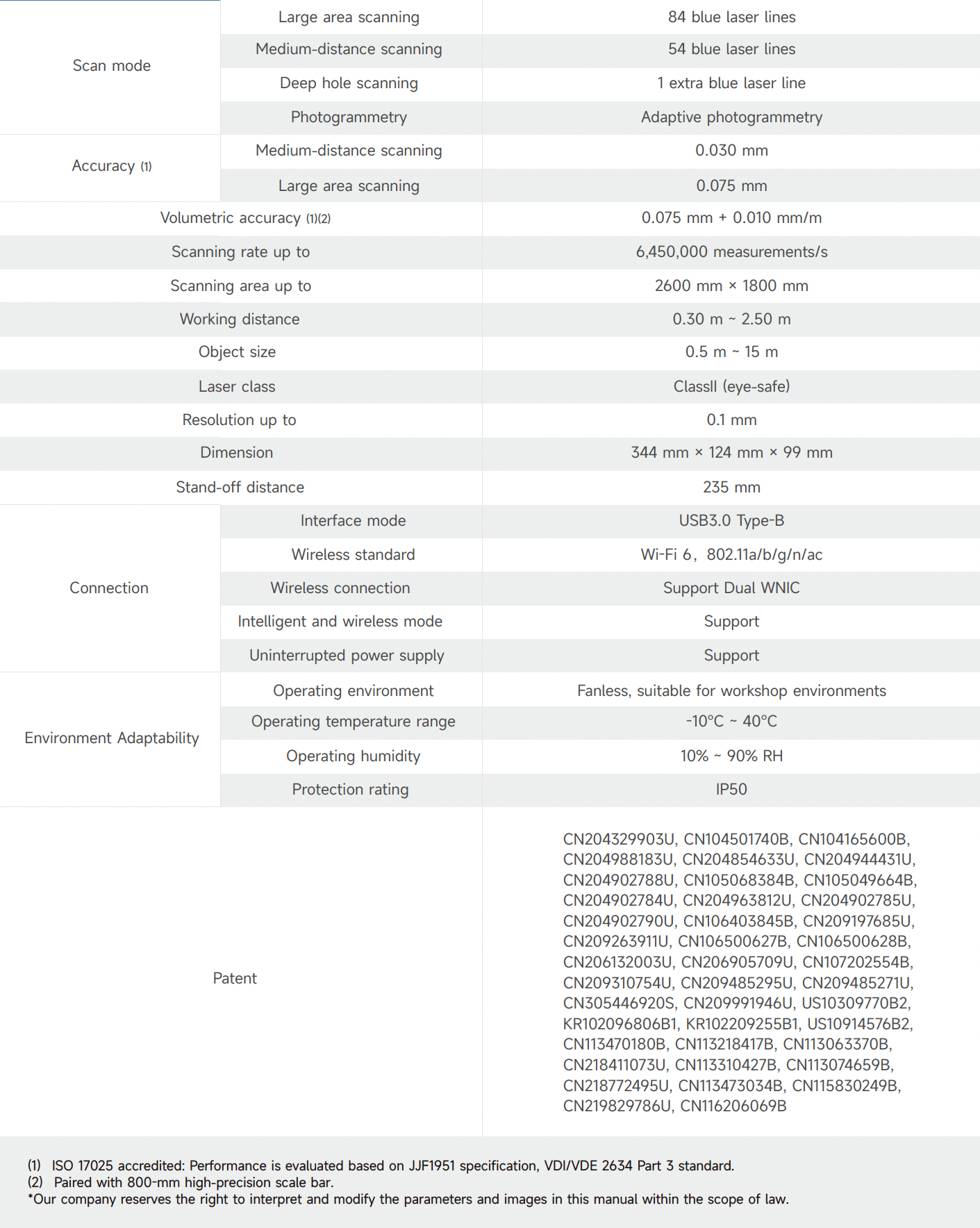

Technical Specifications

- ISO 17025 accredited, performance evaluated per JJF1951 and VDI/VDE 2634 Part 3 standards.

- Paired with an 800-mm high-precision scale bar for enhanced measurement accuracy.

- Specifications and images subject to company interpretation and modification within legal scope.

- Features a dual battery system and dual-WNIC design technology for seamless scanning and wireless operation.

- Ensures consistent volumetric accuracy and eliminates blind spots with advanced adaptive photogrammetry.

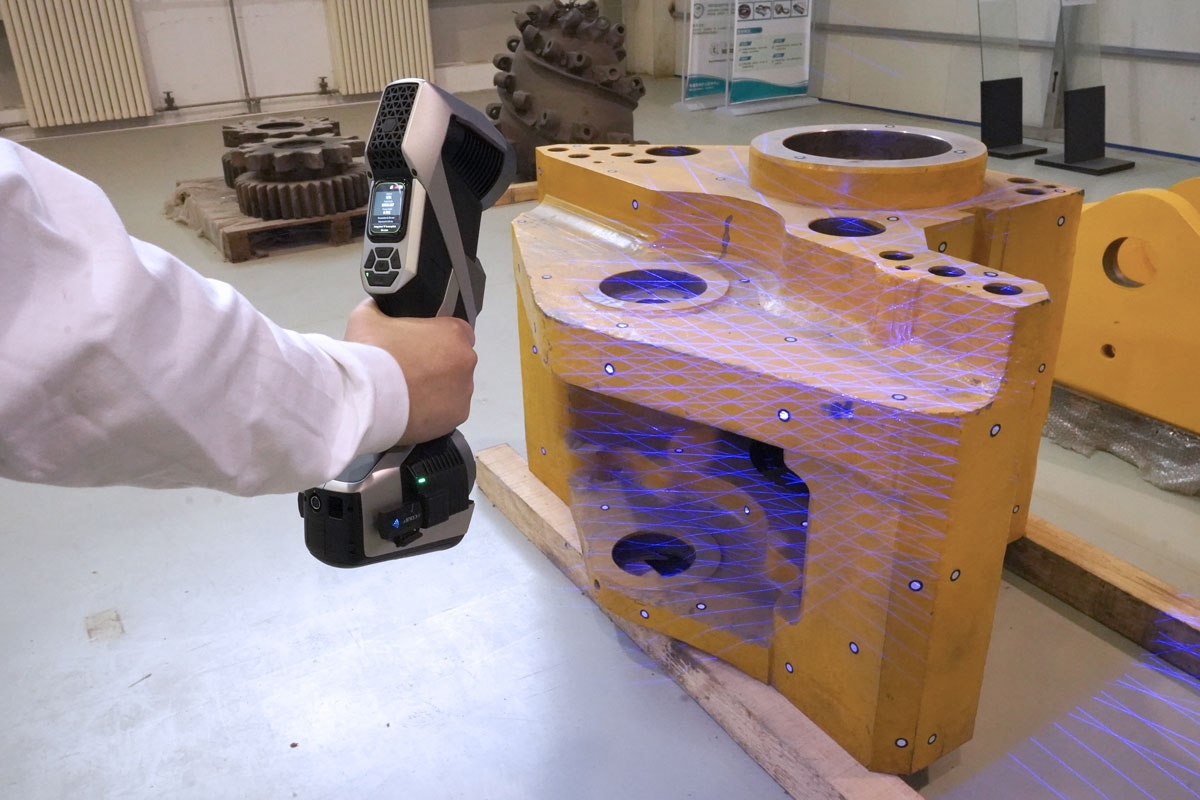

Scanning Capabilities: The KSCAN-X is built for large-scale, precision-driven measurement tasks, capable of capturing ultra-large parts up to 2.6 m — 1.8 m in a single pass with 0.075 mm accuracy. Engineered for complex, industrial-grade components, it supports deep-hole measurement to access hard-to-reach areas such as internal pipes, cavities, and gear teeth. With an extended depth of field ranging from 0.3 m to 2.5 m, the KSCAN-X adapts easily to medium and ultra-large objects, delivering consistent, high-quality data across varying distances and challenging geometries.

Applications: The KSCAN-X is ideal for advanced manufacturing, rail transportation, aerospace, and heavy-industry environments that require accurate, high-resolution measurement of large or intricately shaped parts. It excels in scanning medium to ultra-large components—whether structural frames, welded assemblies, castings, or complex geometries—and provides reliable data for precision inspection, reverse engineering, and design verification. Its fully wireless operation allows technicians to work efficiently in workshop settings, on production floors, or in power-limited environments where mobility and flexibility are essential.

Benefits: With its advanced scanning capabilities and wireless design, the KSCAN-X enhances quality control and significantly boosts inspection efficiency across various industrial applications. It reduces setup time, supports rapid data acquisition, and ensures consistent accuracy, making it a powerful tool for improving workflow productivity. The compact, portable design allows teams to perform high-precision scanning in remote areas, tight spaces, or dynamic workshop environments, enabling faster decision-making and more reliable measurement results.

FAQs About the KSCAN-X Large-Area 3D Scanner